Inoculants are living things, and these bacteria need certain conditions to survive. Dumping them into a tank of pesticide or starter fertilizer can be a pretty harsh environment (1). Luckily, modern inoculants (like those sold by XiteBio®) are technologically designed to contain hearty bacteria. They also come with their own user manuals called compatibility charts. These charts let you know what products are approved for use with your inoculant.

Inoculants support plant fertility through actions like nitrogen fixation and phosphorus solubilization. Modern inoculants are designed to be used in tandem with your regular fertility, pesticide, and/or herbicide program. So, inoculants need to be compatible with other crop inputs used by farmers for example: 10-34, glyphosate, or Cruiser.

Whether you are applying inoculants and chemical inputs by buying treated seed, treating your own seed, or tank mixing and applying inoculant in-furrow, it is important to know just how inoculant compatibility works, what it means, and how it can affect application. Because using the wrong application can result in ineffective bacteria or even plugged equipment.

There are two key aspects that are considered when assessing compatibility: bacterial viability/survivability and physical compatibility.

Bacterial viability refers to how well bacteria survive when in direct contact with other inputs, meaning how long they live once tank-mixed or applied in a seed treatment (2). It is necessary to know how long these bacteria are able to survive in these conditions and also whether an adequate number of bacteria are surviving. This is known as the planting window; it is represented as days on seed (for seed treatments) or hours in a tank mix (2). The number of viable bacteria might be high at the start of this window, but over time they will begin to die off (1). In order to determine the planting window, we conduct tests in our Innovation Research and Development (IRD) facility. Samples are repeatedly taken and tested over time and the number of live bacteria is measured and recorded. Once the number drops below the acceptable threshold, that time frame is determined to be the end of the planting window.

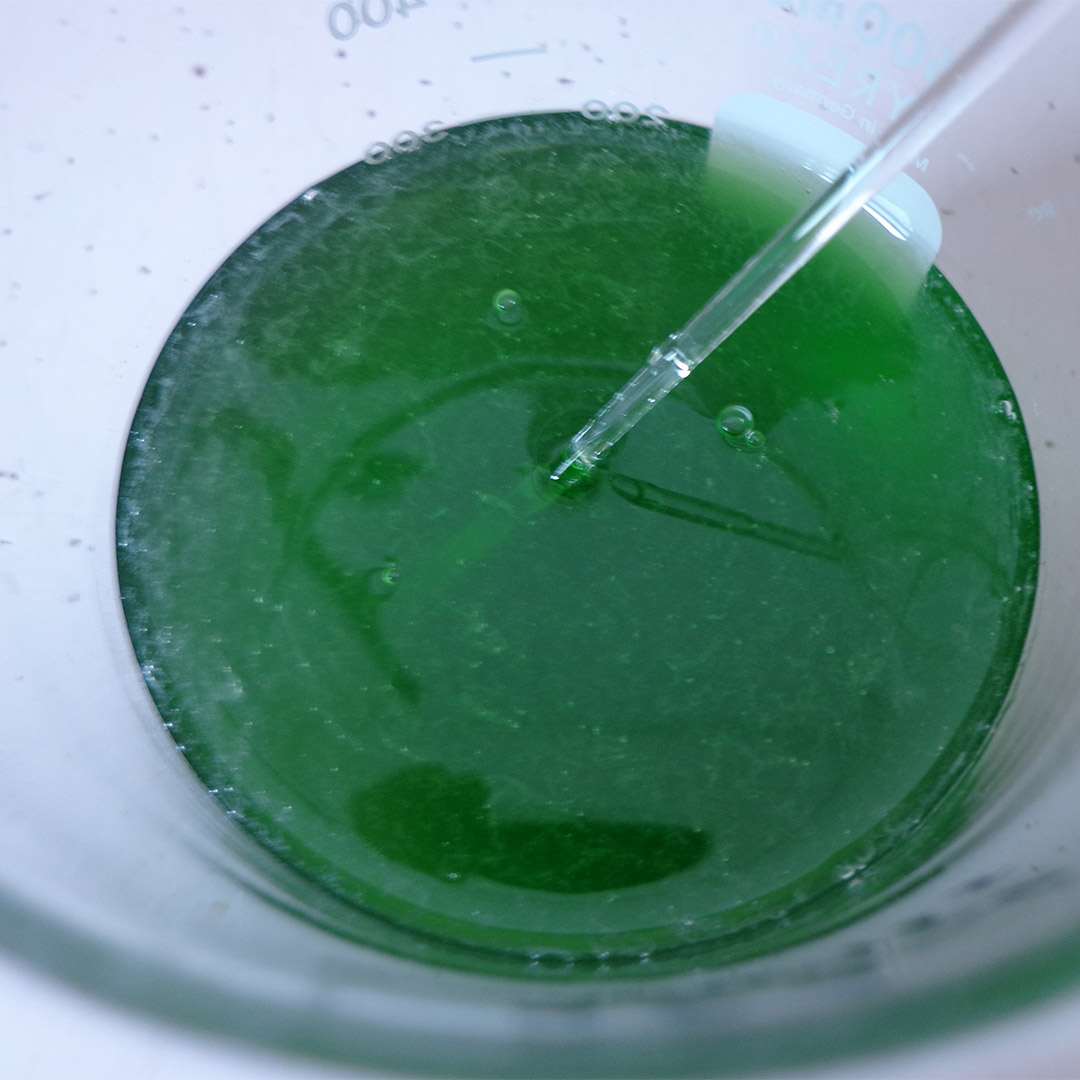

Physical compatibility refers to how well an inoculant or biological will physically mix when combined with other inputs. When bacteria are placed in a stressful environment, they can panic and release a mucous-like compound called exopolysaccharides (EPS) (3). This is a natural reaction bacteria have to help them stay alive. If a product is not compatible and causes stress to bacteria, EPS will be released into the tank and create a stringy mucus that will not flow smoothly and plug up equipment such as spray nozzles (4). However, if an inoculant or biological is physically compatible with a tank mixture of liquid fertilizers or pesticides, it will easily blend throughout the solution and flow smoothly through equipment (4). Physical compatibility is also a consideration between on-seed inoculants and other seed treatments, to ensure that seed is able to flow smoothly and not become too wet or sticky.

Knowing compatibility is vital to successful applications. The IRD team at XiteBio is continually testing and updating our product compatibility charts. Which can be found at xitebio.ca or through your authorized sales representative. Once a product has been added to the chart, growers can feel confident in using it safely and effectively.

Video: Compatibility testing at the XiteBio IRD facility

https://www.youtube.com/watch?v=fgwO6-oUBN0

Resources

- https://www.mdpi.com/2073-4395/11/5/870

- https://grdc.com.au/resources-and-publications/grownotes/crop-agronomy/faba-beans-western/GrowNote-Faba-Bean-West-3-Planting.pdf

- https://www.jmb.or.kr/journal/download_pdf.php?doi=10.4014/jmb.2105.05009

- https://www.youtube.com/watch?v=fgwO6-oUBN0