Inoculating crops with beneficial bacteria is nothing new and has been a common practice for decades. Between peat powder to granular to liquid formulations, there are a lot of options to choose from. So how is liquid inoculant different than granular inoculant? And why should you choose one over the other? In this week’s edition of growing possibilities, we will be highlighting these key differences.

In their most basic forms, granular inoculants consist of small granules (either peat or clay) covered or impregnated with the chosen bacteria (or microorganism) and are applied in the seed furrow during planting. Liquid inoculants consist of a liquid bacteria (or microorganism) suspension in a growing media. Liquid inoculants generally can be applied on the seed surface itself prior to planting or applied in the seed furrow during seeding.

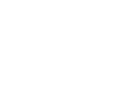

To compare liquid vs granular formulations, let’s start with performance. Granular has been an industry standard for many years and its effectiveness is well proven, but liquid formulas have shown to be just as effective. Our numerous research trials with XiteBio SoyRhizo for soybeans and XiteBio PulseRhizo for pulses have shown these liquid inoculants to perform equal or better than their granular contenders in the field. Performance definitely is important, but equally important to most growers is: how much do I need to buy? Liquid inoculants are usually far more concentrated than granular, and less liquid product is needed to treat the same number of acres when compared to granular. For example, treating 800 acres of lentils with a rhizobial inoculant requires 70 or more bags of granular inoculant while treating the same acres with XiteBio’s liquid inoculant PulseRhizo requires only 5 cases of liquid bags (Fig. 1). This equates to a significant reduction in the storage space required in the warehouse after you have made your purchase.

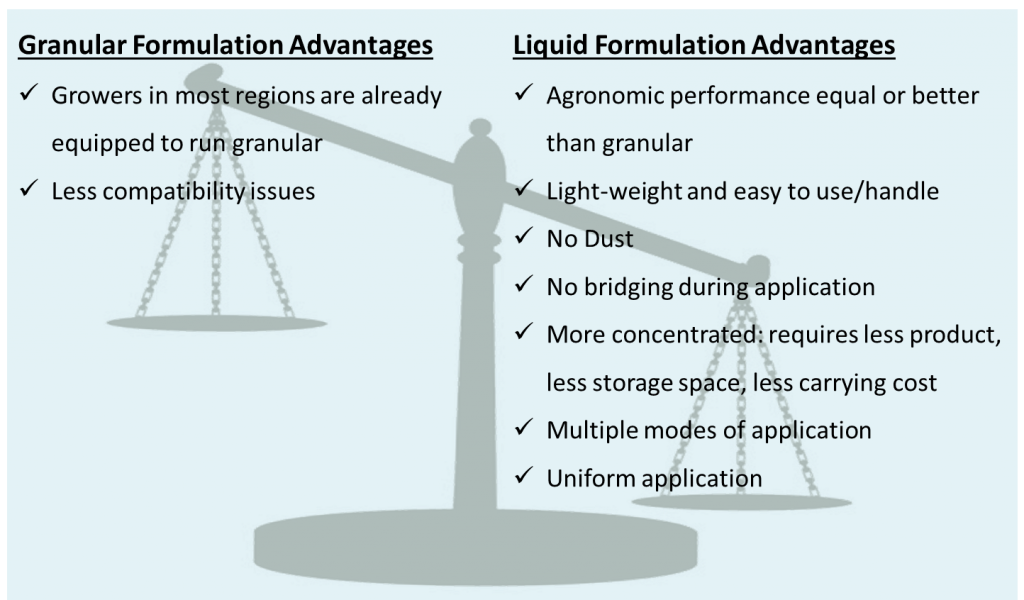

After you have purchased your inoculants, the next step is actually applying them. Granular inoculants can only be applied to the seed furrow during seeding, while liquid inoculants can be applied on the seed surface itself prior to planting or in-furrow during seeding. Loading granular inoculants into applicator equipment is tedious job that requires a lot of heavy lifting and handling time. Liquid inoculants, whether being applied on-seed or in-furrow, are lighter, easier to handle and require less handling time; just dump onto your seed treater/liquid caddy, mix and go. Liquid inoculants are also much cleaner before and during the application.

Applying a liquid inoculant, whether on-seed or in-furrow, requires different equipment than granular inoculants. Some growers may not have this equipment available to them and investing in new equipment can be costly. Because of this, traditionally growers that already have equipment for granular application are often reluctant to switch to liquid irrespective of the advantages the liquid formulation brings.

During the actual application process, both formulations have pros and cons. Granules of inoculant often bunch together and bridge in the hopper of the applicator, meaning granules will not flow out of your applicator. If this problem isn’t noticed and corrected quickly, it can lead to areas of your field being left uninoculated, requiring more passes to go over the missing areas. Liquid inoculants have a different issue: compatibility with chemical seed treatment or fertilizer. When we talk about compatibility we mean physical compatibility a well as bacterial survivability. So, it is utmost important that before using a liquid inoculant with chemical seed treatment or fertilizer you must check the compatibility chart from your inoculant manufacturer.

Deciding on which formulation of inoculant to use is dependent on many factors specific to each grower, but the efficiency and ease-of-use of liquid inoculants provide can be very attractive when making this decision. If you want to try a liquid inoculant next season, see if your preferred inoculant is offered in a liquid formulation or check out https://www.xitebio.ca to see our selection!